Manufacturing

In manufacturing, capital purchases are expected to pay off within three years or you don't have a project. When money is tight the expected return drops to two years. If a project has a payback of one year it is considered a windfall and is rushed through the system. The projects we have completed at James Frugé Consulting typically have a payback of TEN TIMES the investment in the first year. Many projects return 20, 30 or 40 times the cost pf the project.

How Six Sigma Works

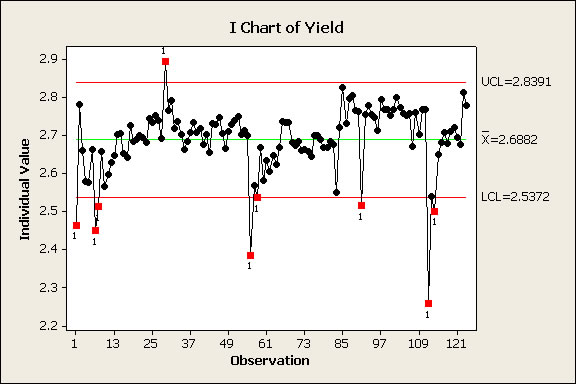

The Six Sigma roadmap, Define, Measure, Analyze, Improve and Control, DMAIC, is well known. Even though the Measure phase is designed to make sure we have trustworthy data in the Define phase we have to use what we have. As my sainted high school math teacher, Lyla Tisdale said, "Do what you can with what you have to get what you want." Most people have some measure of the major output, the Big Y. In a bio-ethanol plant that Big Y is Yield. Some plants calculate a daily yield by measuring the bushels of corn used and the gallons of ethanol produced. It may look something like this.

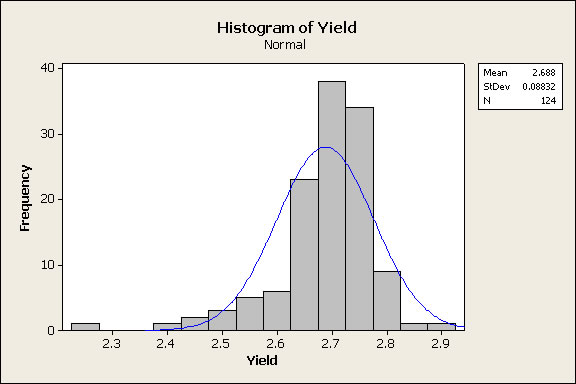

Another way to look at the Daily Yield is the histogram.

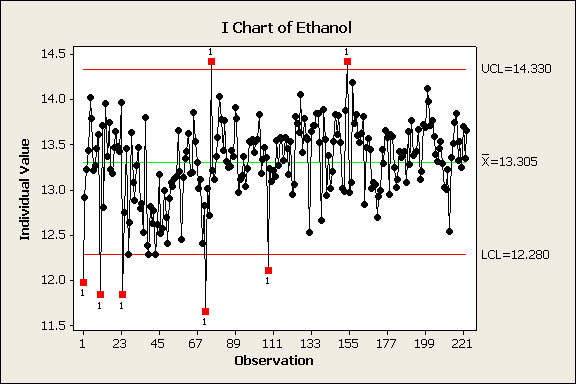

These charts tell us that the average yield was 2.688 which is not terrible but also not very profitable. The bigger problem is the variability. There is no way to predict from day to day if the yield will be 2.95 (average plus 3 standard deviations) or 2.42 (average minus 3 standard deviations. Also, the plant doesn't know why the yield goes up and why it goes down.We can't tie the good days to specific fermentation batches and the bad days to specific fermentation batches. It's hard to measure the bushels of corn used each day so sometimes people use ethanol concentration in the fermentation drop samples as an indication of yield. It may look like this.

We still see a lot of variability and the concentration isn't as high as it should be for optimum yields.We still can't tie a specific batch to it's yield. So the first step is to chose a measurement of performance that is trustworthy and ties performance to inputs we can measure and hopefully control. James Frugé Consulting has developed a batch yield known as YieldCalc® than can be use in the bio-ethanol industry. In other processes the Big Y needs to be measured well.

In the MEASURE phase we establish the measurement of our Big Y (Yield in this case) and then determine what all of the inputs to the process are and how to measure the inputs in a way we can trust. We do measurement system analysis (MSA) on all the inputs and the output. Then, we gather paired input and output data while running the process the way we normally do. Computerized data collection is a must. One product that works well is CFIMS by Algistix. CFIMS makes it easy to gather input data from the process, the lab equipment and manual data and put it all together in an easy to use form.

ANALYZE

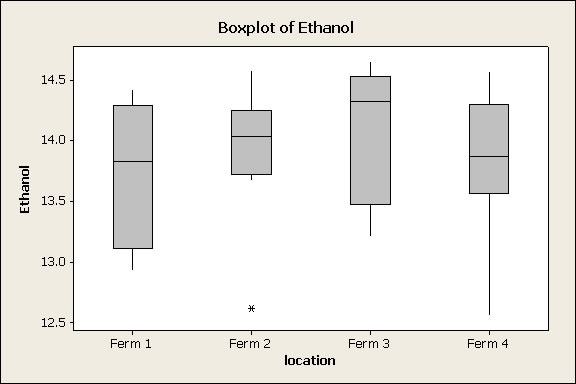

In the analyze phase we use Minitab® to find out which inputs are the important ones. First we analyze graphically and then statistically. Here is an example using a Box plot to see if the fermentor used is an important input.

We see that the median value of ethanol in Ferm 3 batches is higher. Next we want to know is it statistically higher so we do an Analysis of Variants test (ANOVA). This test reveals that the difference between fermentors is not statistically significant. So we look at other inputs. In a typical bio-ethanol plant there are approximately 85-100 input variables that need to be studied. By analyzing the data collected during Measurewe can find the critical few inputs that have the greatest impact on yield.

IMPROVE

In the Improve phase we run a Design of Experiment (DOE) to validate the impact the critical few have and to determine if there are any interactions between inputs.

CONTROL

In the Control phase we set up a system of graphs and activities to make sure the critical few inputs we have discovered are set and remaon set at their optimum values.

Let us help you with your improvement project. The only thing better than a road map is having someone who has been there. We have been working on improving processes using Six Sigma for eleven years. Experience not only gets your improvement faster it helps train your people how to do it themselves.